Artificial Intelligence (AI) Method for Automatic Detection and Recognition of Mechanical Components in Digital Images of Wheelchairs

The wheelchair prescription process involves selecting the type and size of wheelchair and additional postural support or modifications most suitable for the wheelchair user. The are many constituent parts of a wheelchair including frame, seat, backrests, wheels, tyres, controls, brakes, footrests, armrests, cushions etc. Some users require wheelchairs fitted with custom designed and manufactured cushions tailored to their needs. It is very important that the prescription of cushions, wheelchairs and all their constituent parts is fully documented to enable traceability and easy replacement and repair (if necessary) of any parts.

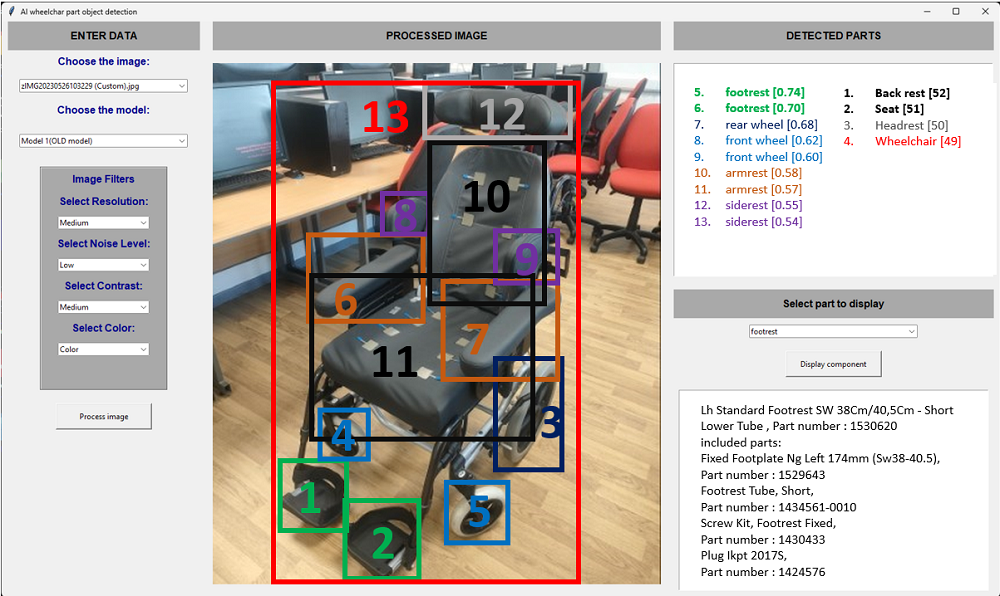

Figure 1. An example of AI component detection software showing the detected parts and catalogue description.

The software application was developed at the University of South Wales in collaboration with Cardiff and Vale University Health Board’s Rehabilitation Engineering Unit to automatically detect and document the constituent parts of a wheelchair. The design and functionality choices of the application were selected via discussions with the staff at NHS Wales Posture and Mobility Centre. Figure 1 shows an example of AI component detection software and display of the detected parts and catalogue description. The core technologies are YOLO8 framework for object detection by ULTRALYTICS, which is the highest performing YOLO model, enabling real-time object detection and segmentation. It uses a neural network, which predicts the objects position and class score in a single iteration. This network divides the image into regions and predicts bounding boxes and probabilities for each region. These bounding boxes are weighted by the predicted probabilities.

Dataset

A bespoke dataset was created in the course of the project to train the YOLO8 model. Extraction of video frames was done from the footage of wheelchair component parts, resulting in a collection of thousands of images to be used for training. The training images were re-scaled to a size of 416x234 as to reduce the computational overhead when training the model. Each image in both datasets were labelled using the LabelImg toolkit.

Conclusions

Wheelchair components often require repairs or replacement over the course of their use.

Unfortunately, they are not readily recognised by people who do not have specialist training in identifying them – this includes patients who rely on them to function in day-to-day life.

The introduction of the technology described in this application will drive improvements in the delivery of the posture and mobility service by:

1) providing more accurate visual documentation of wheelchair and its component parts;

2) reducing the time specialists have to spend documenting the prescribed wheelchair and its component parts;

3) enabling fully automated classification and retrieval of parts based on their shape and function within the assembly.

The proposed solution instantly provides all the specifications of that part, its position within the assembly,

and where they are physically stored in the warehouse thus improving efficiency of service and ultimately the quality of care for wheelchair users.

References:

- Kulon, J., Partlow, A., Gibson, C., Wilson, I. and Wilcox, S. J., “Rule-Based Algorithm for the Classification of Sitting Postures in the Sagittal Plane from the Cardiff Body Match Measurement System,” Journal of Medical Engineering and Technology, vol. 38, no. 1, pp 5-15, 2014. DOI: 10.3109/03091902.2013.844208

- Partlow A., Gibson G., Kulon J., Wilson I., Wilcox S. Pelvis feature extraction and classification of Cardiff body match rig base measurements for input into a knowledge-based system, Journal of Medical Engineering & Technology, vol. 36, no. 8, pp. 399-406, Nov. 2012. DOI: 10.3109/03091902.2012.712202