Applying Knowledge-Based Engineering to Traditional Manufacturing Design

The main aim of the proposed research project is to develop a knowledge-based design tool enabling the generation of hot forging die designs from a component profile. The system integrates the hot forging die design process into a single framework and guides the user through the design process enabling the generation of forgeable geometry from a component profile taking into account machine, material and forging company specific data, and design considerations. The product model manages all the routine engineering tasks. The role of the engineer who interacts with the model is to provide the input specifications such as component geometry, material, and production machine.

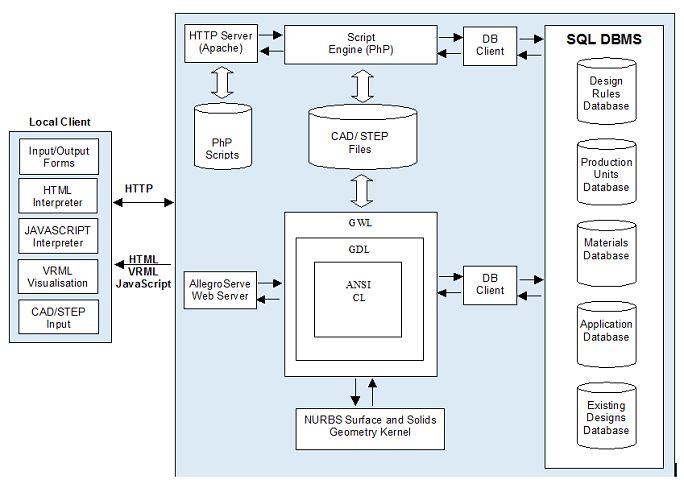

The core of the KBE implementation is the GDL (General-purpose Declarative Language) developed by Genworks International. The GDL follows a non-procedural paradigm for application development and execution, with multiple threads of execution and the ability to load new code and redefine objects dynamically. The GDL is based on a full object-oriented language model, a superset of ANSI Common Lisp. The server side framework is implemented using GWL (Generative Web Language) as an integrated web server-based user interface that manages data and controls other software tools on the server. The GDL/GWL implements caching and dependency tracking. The main application tasks carried out on the server are: accessing the databanks of rules, design features and materials, facilitating files transfer and performing the KBE computations. The GDL/GWL integrates the application logic and databanks through a direct MySQL interface and handles geometry, through its library of three-dimensional geometric objects. The integrated NURBS Surfaces and Solids modelling kernel is based on the SMLib product from Solid Modeling Solutions, Inc. The combination of GDL and SMLib adds powerful surface and solids capabilities to GDL’s built-in 3D wireframe facilities. SMLib provides extensible filleting, as well as full support for non-manifold topology (e.g. edges sharing more than two faces) for boundary-representation solids. It is able to export and import component surfaces directly embedded in IGES format. Figure 1 shows the client and server side arrangements linking the databanks and enabling the inclusion and extraction of data.

Figure 1.KBE Server Architecture

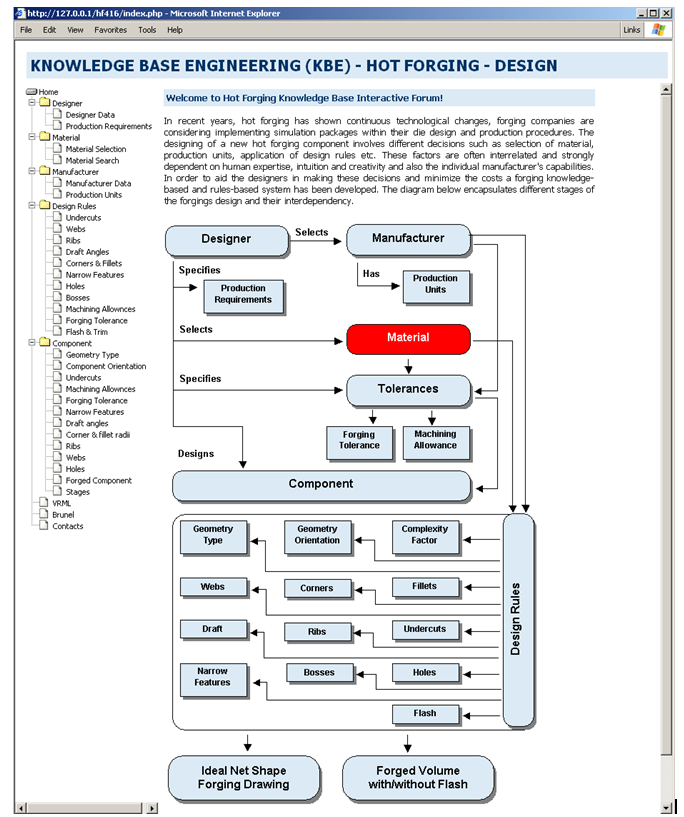

In the KBE system forging company specific databanks of material properties, standards, production unit specifications, design rules are all integrated into the product model through a relational database. The browser-based user interface for accessing the design knowledge is shown in Figure 2. The tree menu on the left allows the selection of several expandable submenus, which in turn update the main viewing window to guide the user interactively through the design process.

The same can be achieved by using the block diagram, shown in the main window

Figure 2. KBE Software User Interface

References:

- Kulon J., Broomhead P., Mynors D. J., Applying Knowledge-Based Engineering to Traditional Manufacturing Design, International Journal of Advanced Manufacturing Technology. Vol. 30(9-10), pp 945-951, October, 2006. DOI: 10.1007/s00170-005-0067-0

- Kulon J., Mynors D. J., Broomhead P., A Knowledge-Based Engineering Design Tool for Metal forging. Journal of Materials Processing Technology, Volume 177(1-3), pp. 331-335, 3 July 2006. DOI: 10.1016/j.jmatprotec.2006.04.062

- Kulon J., Broomhead P., Mynors D. J., The development of a Web-Based Advisory System for Hot Forging Design, Proc. of the 3rd International Conference and Exhibition on Design And Production of Dies and Molds, pp. 147-155, 17-19 June 2004, Bursa, Turkey.

- Broomhead P., Kulon J., Grieve R. J., Mynors D. J., The Development of a Web Accessible Databank of Material Behaviour Characteristics for use in Virtual Design Environments, Proc. of the Fourth International Conference on e-Engineering and Digital Enterprise Technology (e-ENGDET), pp. 229-236, 1-3 September 2004, Leeds Metropolitan University, UK.

- Mccormick G., Broomhead P., Kulon J. and Mynors D. J., Components of design for the superplastic forming process, Proc. of the Fourth International Conference on e-Engineering and Digital Enterprise Technology (e-ENGDET), pp. 93-102, 1-3 September 2004, Leeds Metropolitan University, UK.